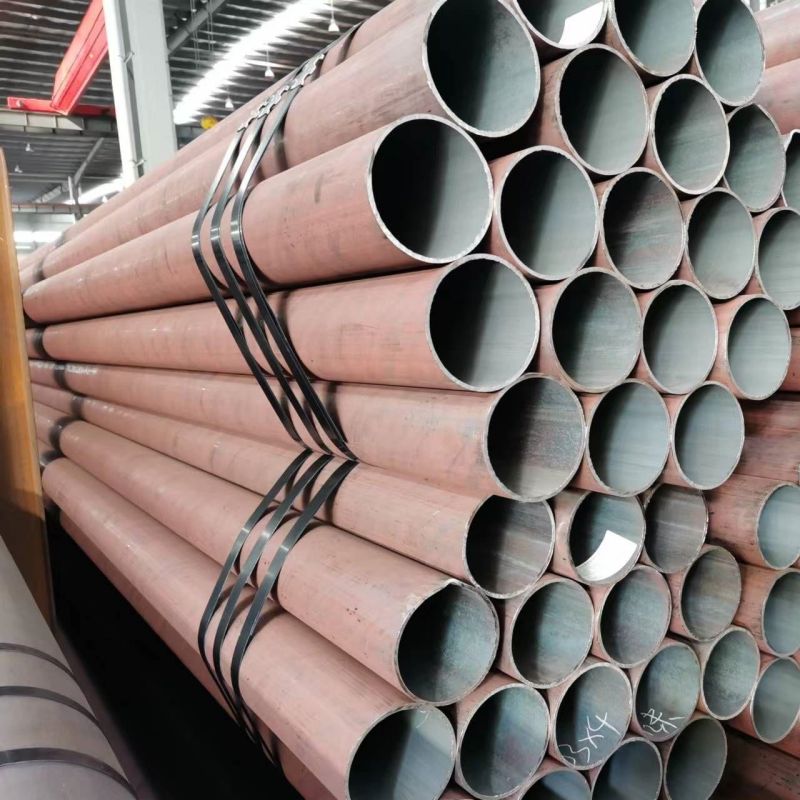

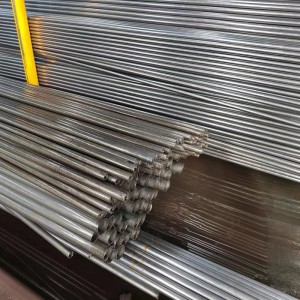

DIN 17175 is designed for elevated temperature purposes, ANSON supplies following steel grades: St35.8, St45.8, 15Mo3, 13CrMo44, 10CrMo910. DIN 17175 seamless steel pipes are widely used in heat exchange appliances. This low alloy grade has significant additions of molybdenum and manganese to it. Besides its use in boiler systems, it is useful for applications in the oil, gas and chemical industry. Generally, these industries make use of heat exchangers, as a means of transference of heat among two or more solutions. The pipes under DIN 17175 are manufactured from carbon and low-alloy steel grades which are resistant to loads under high pressure and temperatures. They are used for the construction of power engineering appliances such as: boilers, heating coils, stoves, heaters, heat exchanger tubes.

DIN 17175 seamless steel pipes are used for boiler installations, high-pressure pipelines and tank construction and special machinery for both high temperature and high-pressure devices(Above 450° high temperature). ANSON is an experienced boiler and pressure steel tube supplier which can offer you DIN 17175 steel pipe of all grade and dimension range.