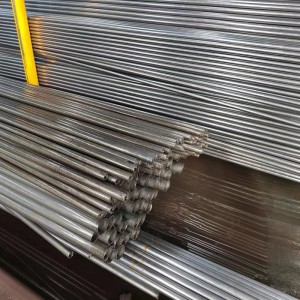

SAE52100 GCr15 Bearing Steel Tube

Short Description:

GCr15 steel pipe is a kind of high carbon chromium bearing steel with low alloy content, good performance and most widely used. After quenching and tempering, it has high and uniform hardness, good wear resistance and high contact fatigue performance. The cold working plasticity of this steel is medium, the cutting performance is general, the welding performance is poor, the sensitivity to the formation of white spots is large, and the temper brittleness is present.

GB/T18254 GCr15 Bearing Steel Tube

1)Standards: Gcr 15, ISO 683/xv11, AISI 52100, JIS SUJ2

2)Chemical composition: C, Cr, Si, Mn, P, S