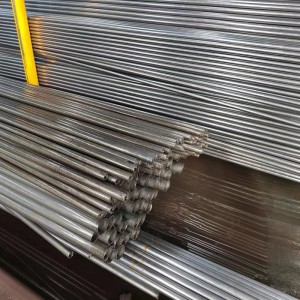

40CrMo 42CrMo 42CrMo4 Alloy Steel Tubooyinka/tubooyinka

Sharaxaad Gaaban:

42CrMo aluminium bir ah oo aan kala go 'lahayn waa bir aad u sareysa oo leh xoog sare iyo adayg, adkeysi wanaagsan, aan lahayn dabacsanaan cad, iyo qallafsanaan yar inta lagu jiro deminta.Deminta iyo xanaaqa ka dib, 42CrMo aluminium biibiile ah ayaa leh xad daal sare leh iyo iska caabin saameyn badan, saameyn wanaagsan oo adkeysi heerkul hoose ah, iyo xoog sare oo gurguurta iyo xoog adkeysi heerkul sare.Deminta dusha sare ee deminta iyo xanaaqa ka dib waxaa badanaa loo isticmaalaa nidaamka daawaynta kulaylka ee 42CrMo aluminium tubooyinka aan xidhnayn.